Manufacturing Capabilities

Manufacturing Capabilities

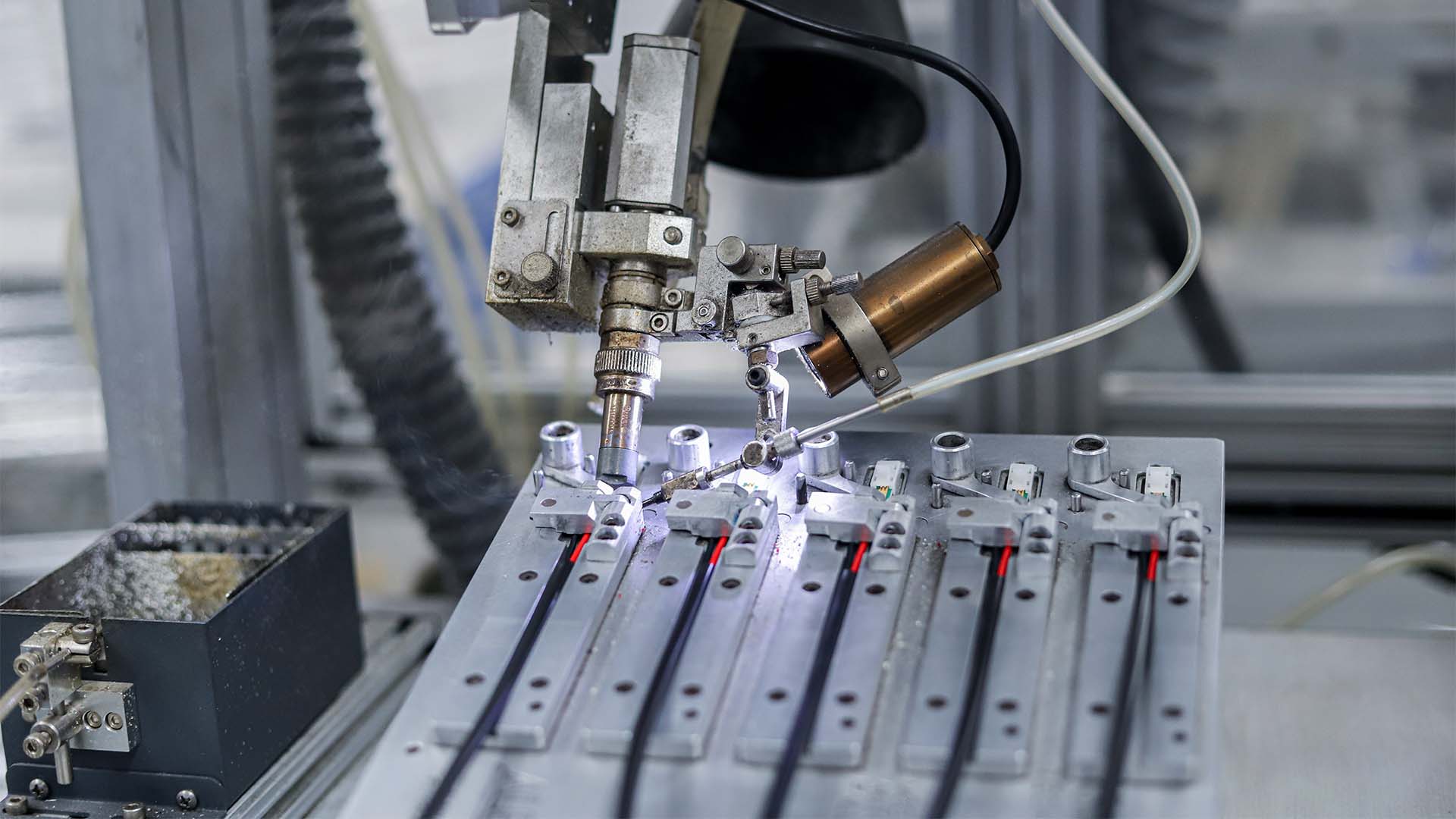

Precision Joining and Assembly Services: Advanced Solutions for Automotive Excellence

At Voltaira Group, we are at the forefront of precision joining and assembly solutions, meticulously crafted to meet the exacting demands of the automotive industry. Our advanced manufacturing capabilities cover a wide range of services, including cutting-edge technologies, sophisticated assembly processes, and innovative protection techniques, ensuring that each component is engineered to perfection and seamlessly integrates into your systems.

Dedication to Excellence

Our dedication to excellence is supported by state-of-the-art technology and a team of highly skilled engineers and operators. We provide customized solutions that enhance the performance, durability, and reliability of your products. Whether your project requires precision in electrical connectivity, mechanical integrity, or fluid-tight sealing, our expertise guarantees superior quality and efficiency at every stage of the manufacturing process.

We pride ourselves on staying ahead of industry trends by closely monitoring the latest developments in precision joining and assembly. Our focus on lightweighting, automation and robotics, multi-material joining, and sustainability ensures that we deploy the most advanced and effective technologies to meet your needs.

In the realm of cutting technologies, we meticulously evaluate each project’s specific requirements during the manufacturing design phase. We consider factors such as composite materials, heat sensitivity, and edge quality to select the most suitable methods.

Our Process

- Our cutting capabilities encompass laser cutting, ultrasonic cutting, CNC machining, and electrical discharge machining (EDM). We adapt our techniques to align with production volumes and specific needs, guaranteeing the highest standards of quality.

- Our pre-integration processes, including stripping, braid trimming, metal stamping, splicing and mechanical/EMPT crimping, are designed to ensure flawless connections during integration. Many of these processes are fully or semi-automated, reflecting our commitment to embracing the latest advancements in modern manufacturing.

- We leverage a range of advanced welding technologies, including ultrasonic welding, laser and remote laser welding, indexed resistance welding, friction stir welding (FSW), and self-piercing riveting (SPR).

- To protect wires and connector terminals, we utilize a comprehensive range of protection techniques. These include molding and overmolding, potting, sealing, housing, and taping fixtures, all designed to provide environmental protection, strain relief, and reinforcement of junction points, thereby protecting your product from moisture, vibration, and other potential hazards.

- Our rigorous testing methods are an integral part of our process. We perform mechanical testing and simulation to validate structural integrity and performance, ensuring that components meet industry standards. We also perform leak testing to ensure the fluid-tight integrity of critical automotive systems, and comprehensive electrical testing (E-testing) to ensure flawless performance under real-world conditions.

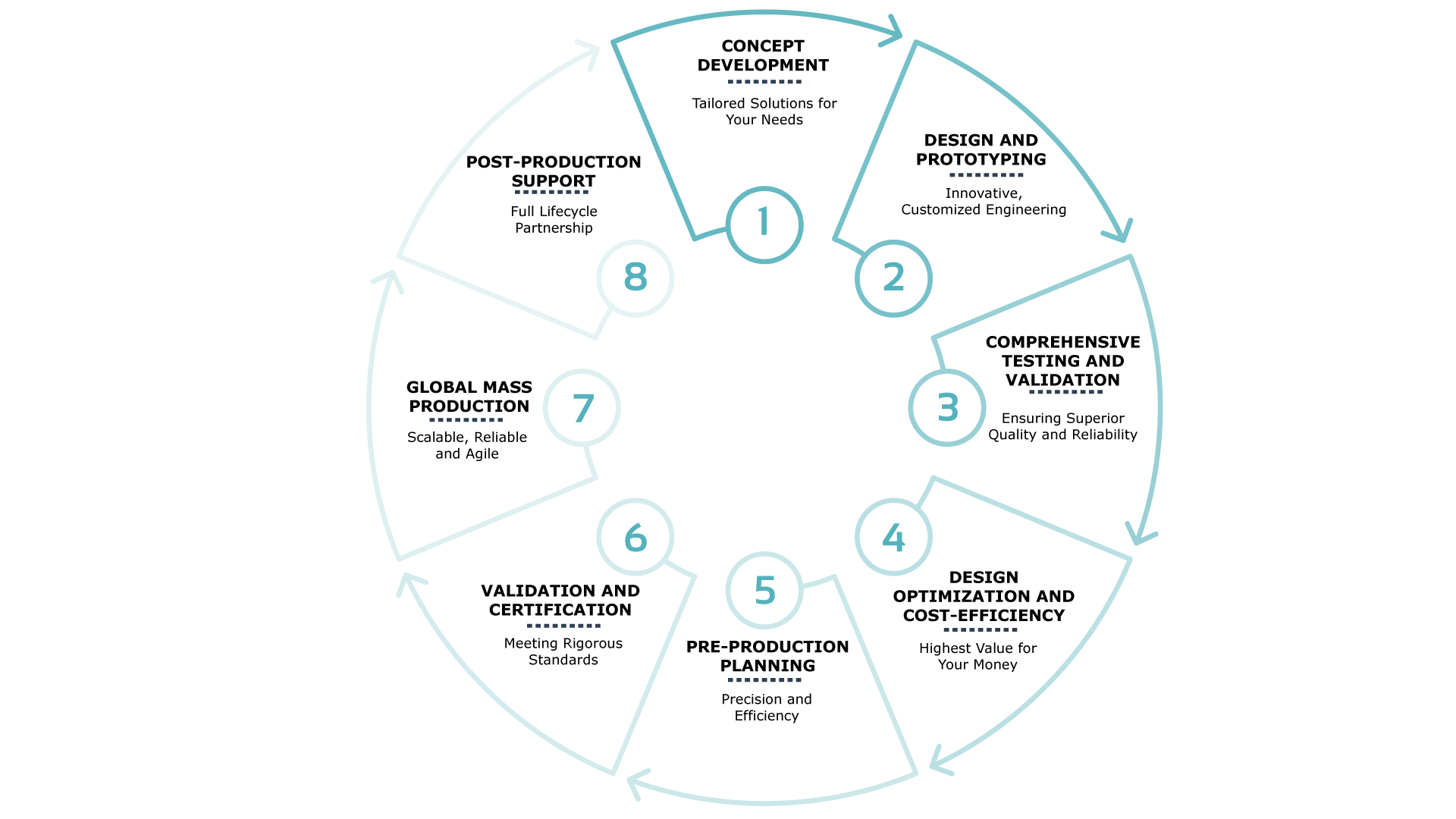

Our Product Development Steps

A 360′ Approach: End-to-End Lifecycle Management

Design and Prototyping: Innovative, Customized Engineering

Our team translates your requirements into detailed schematics, expertly mapping out circuits, connectors, and wire routes. Known for creative solutions and a strong commitment to innovation, Voltaira Group proactively integrates the latest technologies to ensure your success. Whether your challenge involves harsh environments, high safety standards, or space limitations, we deliver customized solutions. Using advanced 3D CAD and routing design tools, we minimize space, weight, and system interference, ensuring seamless integration into your vehicle’s architecture.

Concept development: Tailored Solutions for Your Needs

With decades of experience in the automotive industry, Voltaira Group goes beyond just expertise. We take the time to fully understand your specific requirements—whether it’s power distribution, data communication, or system integration. Our engineers conduct thorough feasibility studies, analyzing factors such as space constraints, connectivity, power requirements, and environmental conditions to design a solution that perfectly fits your needs.

Design Optimization and Cost-Efficiency

After testing, our engineers refine the design through multiple iterations to address any potential issues. At this stage, we also evaluate cost-effectiveness to ensure that the final design meets your budget constraints without compromising performance. Voltaira Group offers in-house tooling and equipment design, uniquely customized to your specifications, ensuring seamless scalability and adaptability for any project.

Comprehensive Testing and Validation

Before production, our prototypes undergo rigorous testing to evaluate electrical performance, environmental durability, EMI/EMC compliance, and mechanical strength. This ensures that each harness can withstand real-world conditions such as flexing, pulling, and abrasion. Our accredited test labs, equipped with advanced technology such as climate chambers, X-rays and CMMs, along with in-house testing and rapid prototyping capabilities, provide fast, reliable results while maintaining the highest quality standards.

Validation and Certification: Meeting Rigorous Standards

At Voltaira Group, we adhere to the strictest automotive regulatory standards and hold all the necessary ISO and IATF certifications. Each product undergoes extensive validation testing on pre-production vehicles to ensure flawless integration with all vehicle systems before mass production begins.

Pre-Production Planning: Precision and Efficiency

Voltaira Group’s expertise covers fully- and semi-automated assembly lines, as well as manual production. We work closely with our customers to create the optimal manufacturing solution, from assembly line design, setup and workforce training to quality control procedures. Our extensive global network and skilled workforce ensure that even the tightest deadlines and most demanding quality standards are met.

Post-Production Support: Full Lifecycle Partnership

Voltaira Group offers comprehensive post-production support, providing our customers with complete product lifecycle management. As part of the Foxconn Interconnect Technology (FIT) Group, we have the agility to scale up or down according to your needs. Our global coverage, vertically integrated value chain, coupled with our in-house tooling capabilities, ensures a rapid response to any changes and guarantees continued excellence in service and delivery.

Global Mass Production: Scalable, Reliable and Agile

With over 30 locations worldwide, Voltaira Group’s manufacturing facilities in Europe, North America, Latin America, Asia, and Africa provide efficient, just-in-time (JIT) delivery and exceptional logistical support. Our commitment to zero-defect manufacturing ensures that every product meets the highest quality standards, and our continuous monitoring processes ensure consistency and reliability across all operations.

More Than a Service Provider

With decades of experience and an unwavering commitment to ZERO-defect standards, Voltaira Group is dedicated to delivering solutions that not only meet but exceed industry expectations. At Voltaira Group, we are more than a service provider—we are your strategic partner in achieving superior quality and efficiency in automotive manufacturing.